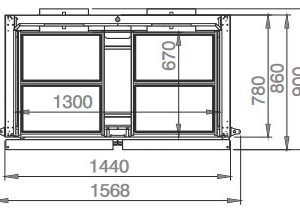

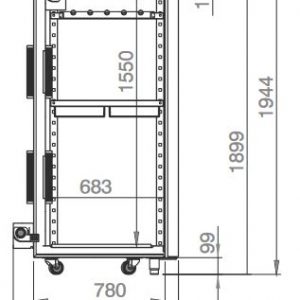

Retarder prover for trolleys

Retarder prover for trolleys

CONSTRUCTION MATERIALS

The entire chamber is made of stainless steel both externally and internally. The insulation is environmentally friendly and reinforced with a thickness of 70mm for optimal energy efficiency.

AIR FLOW

Humidification and heating are produced and distributed through a special group of resistors and fans. The cooling of the products is done through a cooling system that conveys the cold air at a low speed in an indirect and subtle way to the product, completely avoiding the effect on the product.

ELECTRONIC THERMOSTAT

It has a fully programmable thermostat that controls every parameter of the machine, making every processing cycle a success. There are many functions in all phases.

EVAPORATOR

The evaporator is richly constructed with variable speed fans. It is protected by insulated lids which prevent condensate from dripping onto the products during the transition from the cold phase to the hot phase.

ELECTRONIC HUMIDIFIER

Produces plenty of steam through electrodes immersed in water. It is equipped with an electronic card that manages the steam production as well as the washing cycles from salt deposits.

FLOOR

Reinforced with 10 mm resin sheet with non-slip surface

SIDE BUMPERS

All chamber walls are protected by guards fixed to the chamber walls