Retarder prover – Bakery line

Retarder prover – Bakery line

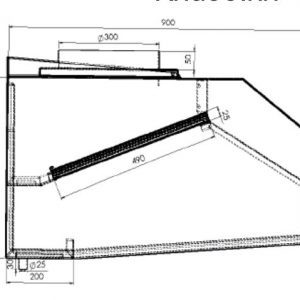

The new model of retarder prover is the best in modern bakery technology to guarantee automatic dough conservation, retarding and proving. Programmable timer: allows bakers to improve not just product quality but also production scheduling 24 hours a day, 7 days a week. The model is manufactured in 3 dimensions for 40×60 trays and for 60×80. The body is made of stainless steel with 75mm insulation (42kg/m³), ventilated cooling.

ADVANTAGES OF USING RETARDER PROVER

• Elimination of night work, because the baker kneads and prepares the different kinds of raw bread during the day, then introduces them in the leavening control appliance and automatically delays the leavening process through simple programming, so that when he arrives early in the morning, the bread is ready to be baked.

• Improved product quality, because a long leavening process gives the bread more flavor and lengthens its duration.

• Enhanced profits, thanks to the rationalization of the production process, causing a reduction in the amount of yeast used and resulting in the elimination of bread remains at the end of the day.

FUNCTIONS

• Neutral-zone temperature and humidity control.

• Programming of four work cycles.

• Double fan speed.

• Hot and cold manual cycles.

• Management of cooling, storage, leavening and product-ready settling phases.

• Clock and calendar to set product-ready time.

• Luminous synoptic display indicating program progress end of the day.

MAIN CHARACTERISTICS

• The electronic controller consists of the 100Master PAN unit, on which all the electrical connections are made, and the keyboard/display, which features a large LCD screen providing complete information on room status.

• The overall unit allows control of cold, heat, ventilation, room light, humidification, dehumidification, defrosting and alarms via control of the NTC ambient and evaporator sensors and the 4-20 mA humidity sensor inputs.

• Compressor and fan safety devices, door switch, humidifier alarm.

• Special power boards complete with the controller can be supplied according to customer-specified requirements.